This post is a followup from my post here about my Electric Imp based Temperature and Humidity sensor.

I left my sensor my the deck of my apartment starting on January 25, 2015 and it has been running up until September 17, 2016 on the same set of batteries. For the past almost 22 months it has woken up every hour, read the temperature and humidity and posted it to the internet.

This is the temperature data measured by the Silicon labs Si7021 Temperature/Humidity sensor:

There may be some erroneous readings as I don’t think the temperature spiked up to 50° C on my balcony but overall the readings usually seemed believable.

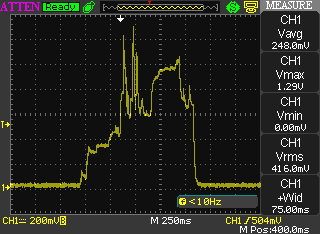

Here are the battery voltage measurements over the course of the test:

There is the occasional spike down where i believe it was a day where the electric imp servers had down-time or the electric imp software had an update where the device was online for longer than expected. One bug I noticed was that if the servers were down it would stay online trying to communicate with the electric imp servers and drain power. To improve this there should be a timeout implemented where if it cant communicate with the servers after a couple seconds it will give up and shut down, but I will be the first to admit I am not the best embedded software developer.

Overall I was impressed with the amount of battery life that I was able to get out of this mostly due to the low sleep current of the electric imp.

Another idea to improve the battery life would be to use a low power timer to cut the power to the WiFi device when sleeping instead of using sleep function of the microcontroller

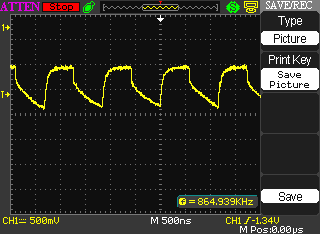

http://www.ti.com/lit/ds/symlink/tpl5100.pdf

This has a current consumption of 30nA compared to the ~8uA of the electric imp’s sleep mode. Which could be set to periodically wake up the microcontroller and then cut the power so that the sleep/off current is extremely low.

Andrew